x

Post

Consult

IM

Feedback

Top

Product Description

PRODUCT FEATURES

| Process and supporting product system | Process and supporting product system | White, Green, Yellow or customize |

| Colour | ||

| Density (after mixing) | 1.24±0.2g/mL | |

| Volume solids (%) | 46±2 | |

| Flash point | no | |

| Volatile organic content | 80g/L | |

| luster | Light, matte | |

| Weather resistance | Excellent | |

| Light retention and color retention | Excellent | |

| Water resistance | Good | |

| Flexibility | Excellent | |

| Wear resistance | Good | |

| Application scope | The outdoor products are used for bridge, ship, chemical industry, electric power and other steel structure surface.High decorative finish | |

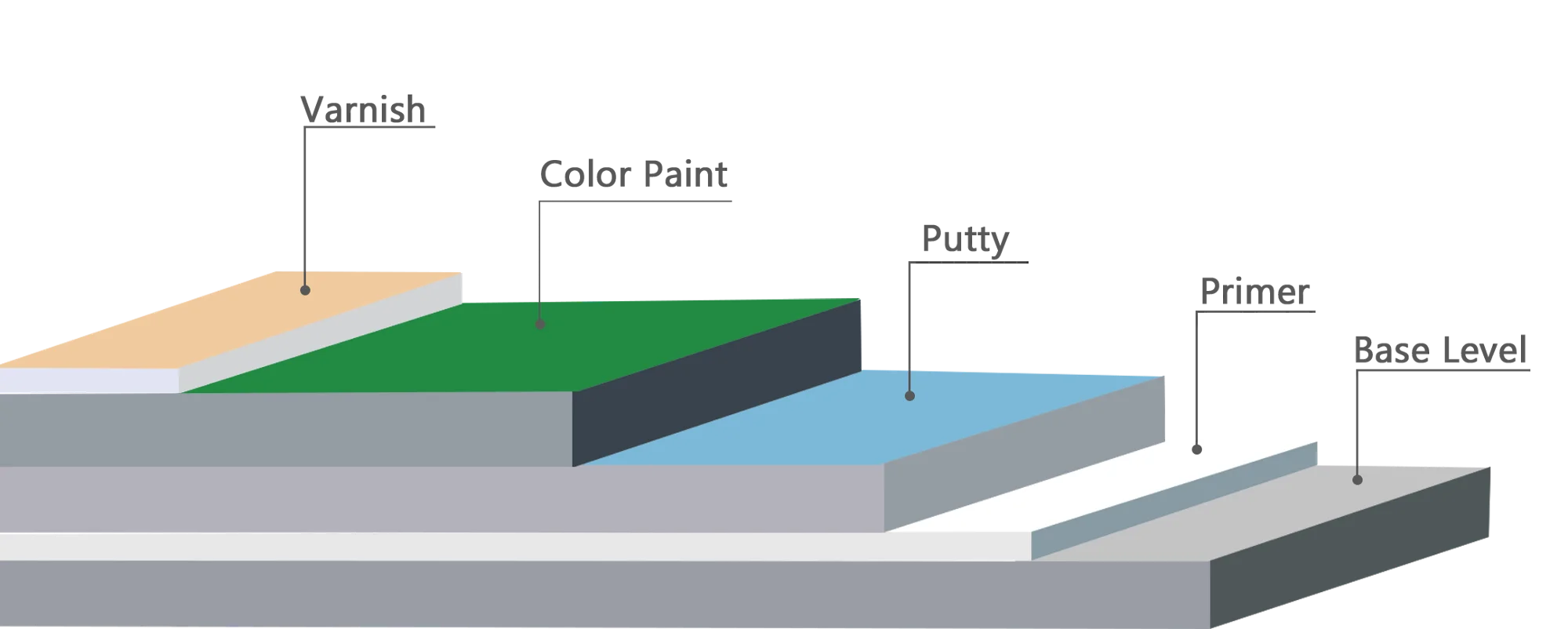

| Process and supporting product system | Flowable closed primer + mobile mortar coating + putty coating + polyurethane topcoat |

TYPICAL COATING STRUCTURE

| PACKAGING | 5 Litre & 20Litre Drum |

| DESCRIPTION |

Polyurethane has a high build gloss finish when dry. It cures quicklyand is suitable for use over a range of temperatures and has UV protection added. It is a clear liquid with slight yellow tinge and a pungent odour. A single pack, high performance, moisture curing polyurethane.

|

| FEATURES |

Non YellowingHigh BuildHard, very durable coatingGood dry and through cureExcellent mark and scuff resistanceExcellent chemical resistanceExcellent anti-graffiti coating

|

APPLICATION MATERIAL SAFETY DATA SHEET MUST BE READ BEFORE OPENING THIS PRODUCT.

The base product should be dry containing no solvent or moisture as once the Polyurethane is dry it can help trap moisture or solvent underneath which could cause the sealer to lift. Previously coated substrates should be checked for solvent resistance and compatibility in both their wet and dry states. Sound substrates need to be thoroughly sanded to provide a surface key. There should be no contaminates which could lead to loss of adhesion. For porous surfaces the first coat must be diluted to penetrate into the substrate and provide better wetting. Dilution can be up to 50/50 with xylene solvent. If there are doubts about application or appearance, test a small area first. Diluted sealer must be used immediately and not stored or returned to the original sealer. Decant the quantity of Polyurethane required for immediate use only.The original container should be resealed immediately to prevent moisture getting in. Apply Polyurethane either by brush, roller or airless spray. For spray, applications between 5% -10% solvent can be added, this will shorten the pot life. A slip resistant additive may be required particularly if the area gets wet. |

Technical Data Sheet

TOP COATING

Re-coating should be within 16-18 hours depending on conditions prevailing. If too much time is allowed for cure, adhesion can be difficult to obtain on subsequent coats. If too much time has elapsed then the first coat will have to be sanded to provide extra key before the 2ndand 3rdcoats are applied.

NOTE

Do not pour Polyurethane back into the original container. In doing so contamination in particular moisture can be included which will result in a shortened shelf life of the original material.

USAGE RATE

1 X 20Litre drum covers approximately 48 to 100m²(two coats) or as specified depending on surface texture.

SPECIFICATIONS

| RESIN TYPE | Single pack industrial grade self curing system |

| COVERAGE RATE | Approx. 5-10m² per coat and depending on surface texture |

| RE-COAT TIME | 6-16 hours depending on temperature |

| S.G | 0.98 (19.6kg / 20Litres) |

| NCO | 2.8 –3.1 |

SOLVENT RESISTANCE

| Xylene | Very Good |

| M.E.K. | Poor |

| Petrol | Very Good |

| Oil | Very Good |

| 40% SulphuricAcid | Very Good |

| 40% Caustic Soda | Very Good |

| 50% Acetic Acid | Very Good |

| De-ionised water | Excellent |

LIMITATIONS

Needs moisture to cure hard.Low humidity inhibits cure. When thoroughly dry, a mist of water over the polyurethane will accelerate cure. The use of xylene as a softening agent for re-coating is essential to improve inter-coating adhesion. When resealing Polyurethane, it is advised to lightly sand the old coating to help with adhesion.

STORAGE

Recommends storage in a cool, well ventilated space away from heat sources. Keep tightly lidded. Keep away from reducing agents and strong oxidizing agents. Take precautions against static electricity discharges. See State and Federal Regulations as to storage.

SHELF LIFE

6 months in un-opened container stored as recommended. After this time product should be checked to ensure suitability for use.

DISPOSAL

Contaminated absorbent to be disposed of in a secure land fill in accordance with local bodies , state and or federal authorities.

PRECAUTIONS

After sealing, it is recommended that the sealed surface be protected from foot traffic for a minimum of 48hours. Vehicle traffic for a minimum of 72hours. Time required depends on weather conditions coating thickness etc. Therefore check suitability before allowing traffic.

PRODUCT WARNING

Maiqi Coatings has no control over the use or storage of this product and therefore does not accept any liability in this regard. Any verbal advice given should not be regarded as authoritative information. This information is subject to change without notice, therefore all applicators should ensure they have current information. This product is intended for the use only of skilled tradesmen and where applicable, statutory licensed tradesmen experienced and trained in the use of this product. This product is warranted to be of uniform quality within the manufacturer’stolerance. This manufacturer has no control over the use or misuse of this product, therefore no warranty rests or implied, is or can be made either as to the effects of such use. The manufacturer’sobligations shall be limited to replacing product proving to be defective.

Products Application

Verification Failed:

Verification Failed:

Comments

Feedback from Buyer