x

Post

Consult

IM

Feedback

Top

Product Description

PRODUCT FEATURES

| Color | Custom |

| Resistance to impact, Mpa | <=10 |

| Resistance to abrasion, 500g/1000r | <=0.02 |

| Resistance to 30% H2SO4, 30 days | Slight changes |

| Resistance to 30% NaOH, 30 days | No changes |

| Theoretical spreading rate, g/m2 | 150-200 |

| Recommend DFT, mm | 1 |

| To touch, hours @ 20 oC | <= 4 |

| To handle, hours @ 20 oC | <= 24 |

| Mixing ratio | Part A : Part B = 4 : 1 |

| Packaging | Part A:20 kg in an iron barrel Part B: 5 kg in an iron barrel |

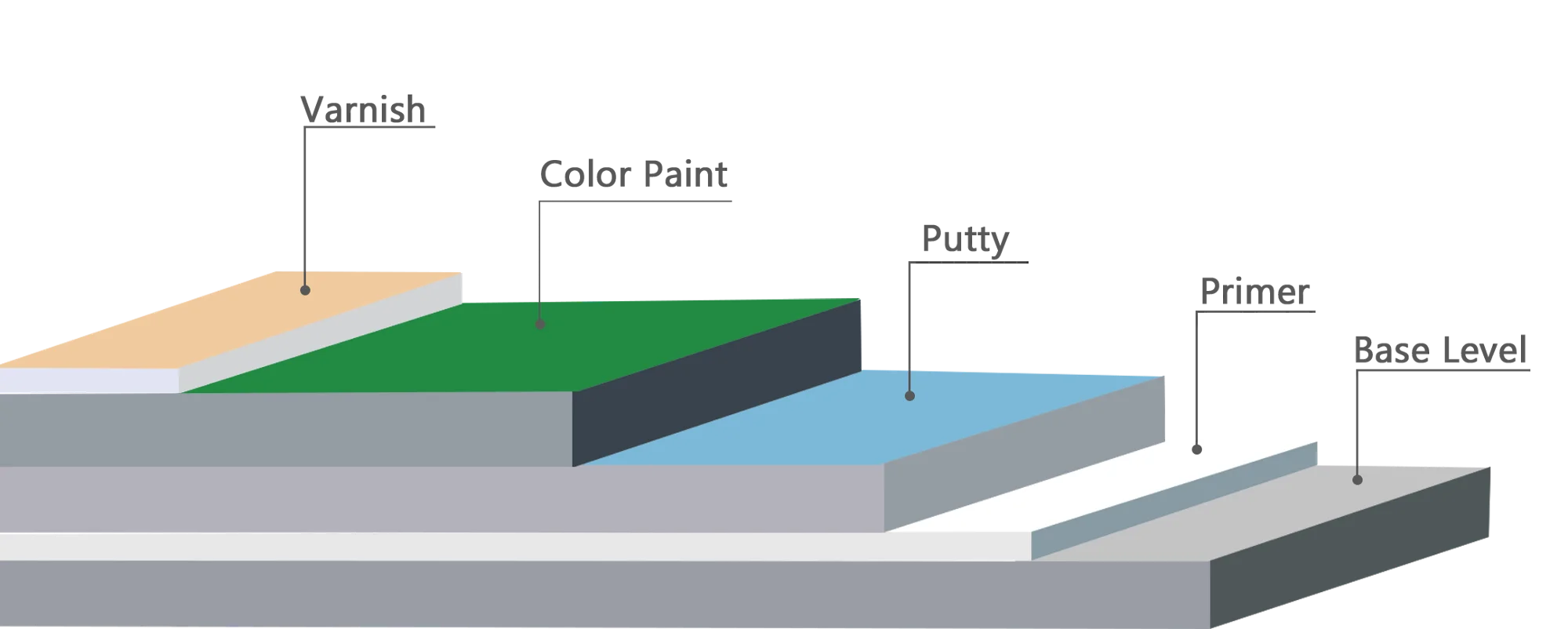

TYPICAL COATING STRUCTURE

| Project | Component A | Component B | ||

| Hours of use | 2h(10℃) | 1h(25℃) | 45min(30℃) | |

| Curing time | Surface dry | 12h(10℃) | 8h(25℃) | 3h(30℃) |

| Hard dry | 48h(10℃) | 36h(25℃) | 24h(30℃) | |

| Over weight | 7days(10℃) | 4days(25℃) | 2days(30℃) | |

| Dosage | 1.55±0.55 | 0.95±0.02 | ||

| Color | Optional | Soft yellow | ||

| Proportion | Component A : Component B=5:1 | |||

| VOC | ≤2% (after mixing) |

Technical Data Sheet

| Product | MQ-146 Epoxy self leveling floor paint |

| Type | Topcoat |

| Appearance | High gloss and smooth,mirror effect |

| Features | Oil based, two-component, solvent free,super wear resistant |

| Advantages | Super high-performance 3-layer coating system that uses a 2 part epoxy primer, 2-part 100% solids high build epoxy coating and 2 part military grade protective topcoat. |

| Application | Indoor concrete floor: parking lot, warehouse, electronics factory, food factory, chemical plant, machinery factory, shopping center, hospital, school,office, etc. |

| Color | Custom |

| Resistance to impact, Mpa | <=10 |

| Resistance to abrasion, 500g/1000r | <=0.02 |

| Resistance to 30% H2SO4, 30 days | Slight changes |

| Resistance to 30% NaOH, 30 days | No changes |

| Theoretical spreading rate, g/m2 | 150-200 |

| Recommend DFT, mm | 1 |

| To touch, hours @ 20 oC | <= 4 |

| To handle, hours @ 20 oC | <= 24 |

| Mixing ratio | Part A : Part B = 4 : 1 |

| Packaging | Part A:20 kg in an iron barrel Part B: 5 kg in an iron barrel |

Application

Verification Failed:

Verification Failed:

Comments

Feedback from Buyer