x

Post

Consult

IM

Feedback

Top

Product Description

what is the appliation of floor deck making machine?

The decking floor production line can finished products of metal floor deck.They have many features,such as high precision,accurate shape and size,large wave height and good adhesiveness .Otherwise,the production can be overlap well .In the high story building,it not only can save steel mould board,but also reduces the steel amount of engineering useage.

We have two kinds of decking floor making machine as the follow picture show.One adopts vertical arch frame structure and guide pillar hydraulic cutting system. Independent roller station formed the main roll former and make the machine more beauty and steady.The other uses middle plate structure and the transmission is by chains.

processing flow diagram of floor deck making machine

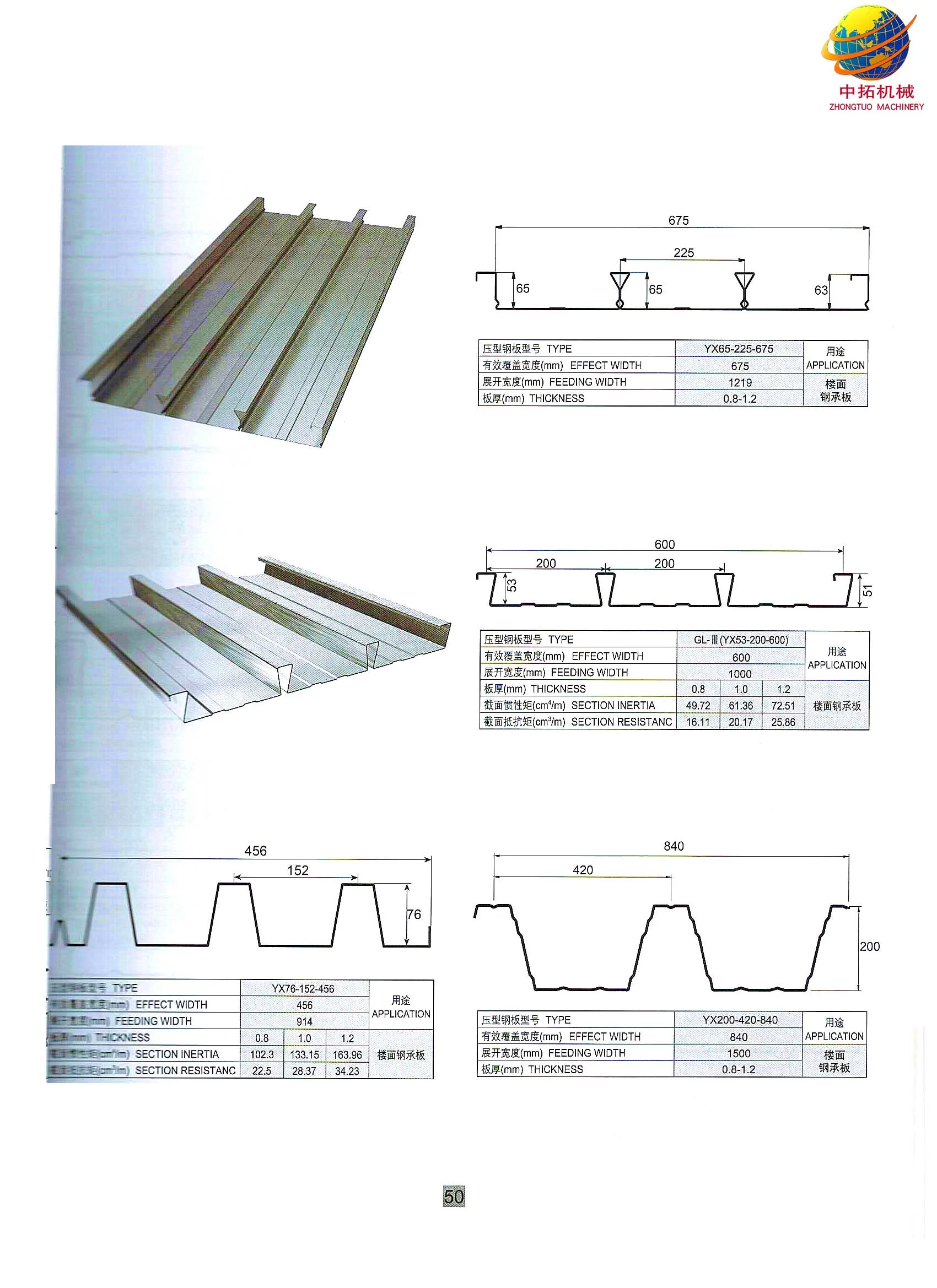

some profile drawings for high quantity metal steel sheet decking floor production roll forming line

technical parameters of floor deck making machine

name | decking floor making machine |

Roller steps | 25 |

Dimension | 12000*1600*1550mm |

Weight | 11t |

Forming thickness | 0.7-1.2mm |

Large frame | 450mm H-Beam |

Diameter of roller | Φ90mm |

Middle plate | 22mm |

transport | chain or gear |

Voltage | 380V 60HZ 3 PH or customized by your require |

Motor power | 11kw+11kw |

Pump station power | 3kw/(5.5kw hydraulic motor) |

Transducer power | 11.5kw |

Cutting system | Hydraulic cutting by pillar type(avoiding noise and smooth cut) |

Material of cutting | Cr12 |

Control system | PLC brand :Taida / Panasonic |

Length error : ±1mm | |

work speed | 8-12m/min |

Warranty | 1 year and we provide technical support for whole life, and overseas service.Some parts are available. |

details of floor deck making machine(middle plate structure)

Manual decoiler

The decoiler can support the raw material and making uncoiling .We can provide 5 tons,10 tons decoiler for you to choose.

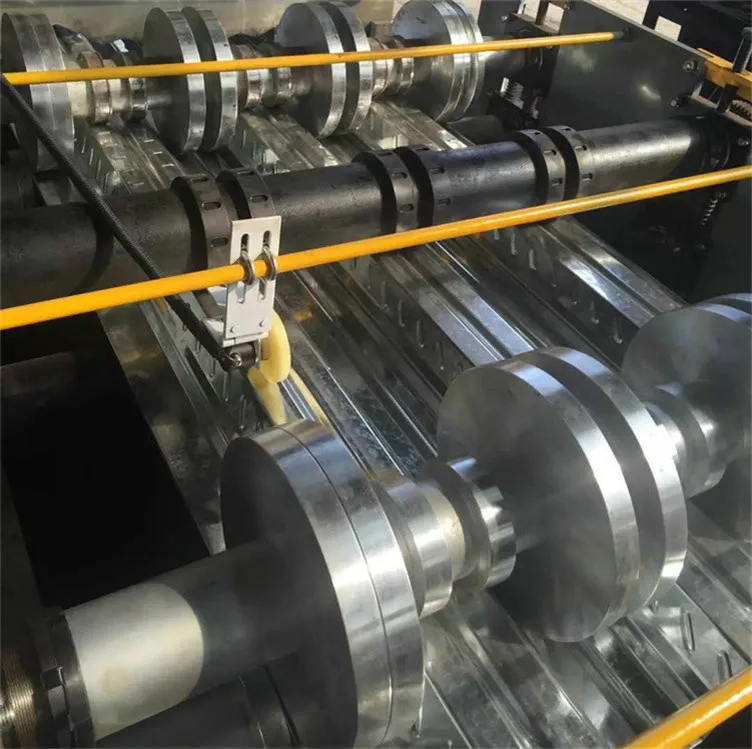

main forming machine

In order to protect the products shape and precision ,we take use of the middle plate welded frame structure.and drive by chains.

(From The first roller station to the last roller station, the up and down use the chain drive transmission.)

Before forming the sheet, can add embossing system.

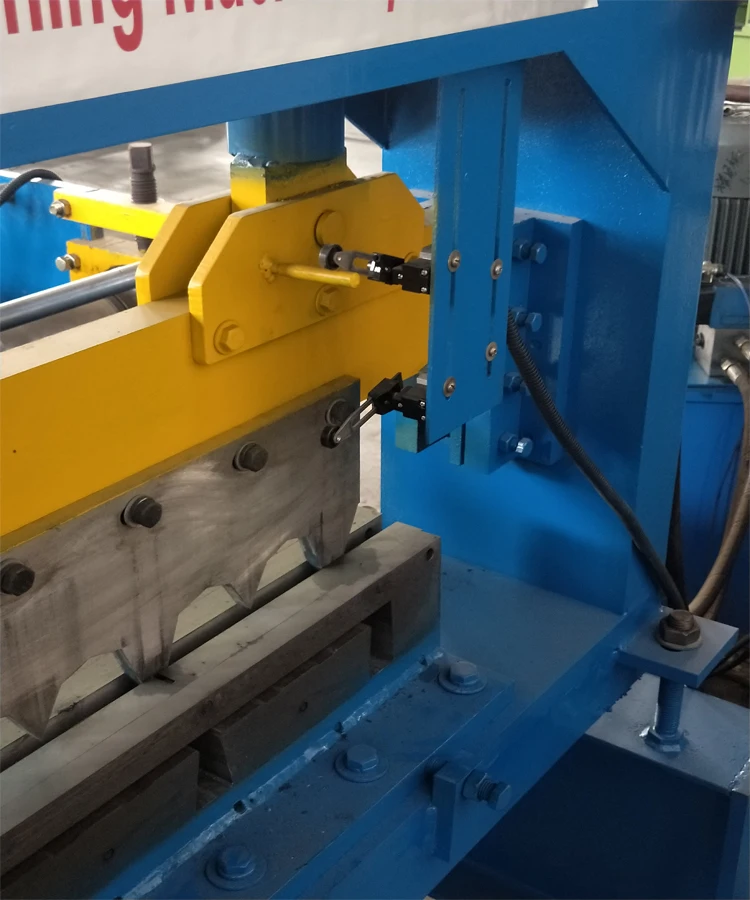

Hydraulic cutting system:

Best quality hydraulic driving, the cutter is make as two pieces of blade.

Hydraulic station is controlled by the oil pump.The hydraulic oil into the oil box, and after start the oil pump, the knives will start work and the main forming machine wil stop at the same time.

PLC control

Computer control length and quantity,Reach the set length automatic cutting machine,when it get the setting quantity, it automatic stops.

More details of floor deck making machine

please look at the photoes

Company Information

Cangzhou Zhongtuo Roll Forming Machinery Co., Ltd is a professional manufacturer and has been dedicating to roll forming technologies for over 2 decades. Now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients.All products comply with international quality standards and are greatly appreciated in markets throughout the world, such as Asia, Africa, Europe,South America, Australia and so on.

We specialized in manufacturing color steel roll forming machine, glazed tile roll forming machine,light keel roll forming machine, C/Z purlin roll forming machine, floor deck roll forming machine, cable tray roll forming, shutter door roll forming machine, downspout machine, welded pipe roll forming machine, slitting machine and other cold roll forming machine.For metal processing, we have slitting machine, cutting machine, You can believed that we can help build a better future for you and your customer.

FAQ2

1. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours), then we can pick up you.

2.How to get a quotation?

a.Give me the profile drawing and thickness,this is the important.

b.Other spicific requirements is welcome,such as the speed,power and voltage you want.

3.How about the machines for testing?

A:Warmly welcome to our factory supervise and inspect anytime;

B:We will arrange the machine test in our factory before the shipment.

C:If the customer can't come, we will provide the machine running video and photos to them.

4. How can I install my machine when it arrives?

A: We will send technician to install and train your people to use machines if required.If you need,our engineer will go to your factory for teaching.

5.What about your warranty?

A:Our warranty is 1 year, all machine part can be replaced for free within 1 year if broken(not including man made).And offer life time after sale service.

Verification Failed:

Verification Failed:

Comments

Feedback from Buyer